By Bob Sims

July 2021

Playin' it

Safe

Legislation, science and culture have all been variables in the evolution of food and worker safety.

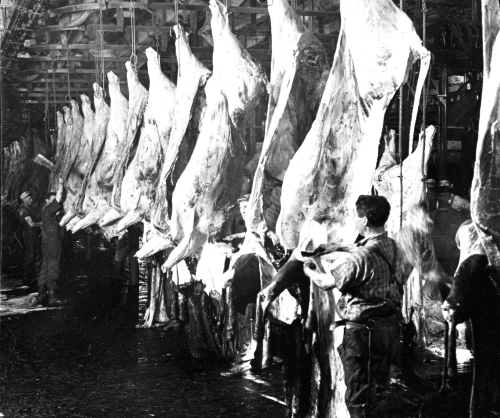

Library of Congress Public Domain

In 1905, an event outside the meat processing industry forever changed its trajectory. That year marked the first publication of Upton Sinclair’s now classic novel, “The Jungle.” The work of fiction depicted the unsavory conditions of the meat packing industry in the United States. Sinclair spent seven weeks working in the packing houses of Chicago to gather experiences for the book. Those experiences gave the author the details necessary to write a book that brought change to an entire industry through legislation, specifically the passing of the Meat Inspection Act of 1906.

This event and others marked monumental shifts throughout the evolution of food safety in the meat packing industry. They set successive changes in motion and pushed food safety and consumer well-being to the top of the priority list for meat processors in the United States.

Early Acts

President Theodore Roosevelt read “The Jungle” and sent labor commissioner Charles P. Neill and social worker James Bronson Reynolds to Chicago, and through their Neill-Reynolds Report, the two confirmed the details of Sinclair’s descriptions of the meat packing houses in his book. Congress then passed the legislation and President Roosevelt signed the Meat Inspection Act of 1906 into law. While “The Jungle” highlighted worker safety, it essentially created the impetus for food safety, as well.

The Meat Inspection Act of 1906 reformed the meat packing industry in the United States and set standards for sanitation and safe food for human consumption throughout the industry. It established a statute that prohibited the sale of misbranded and adulterated livestock, and the food products derived from that livestock, and ensured slaughter and processing occurred under sanitary conditions. Also, the law mandated the US Department of Agriculture (USDA) inspect all cattle, swine, sheep, goats and horses processed for human consumption before and after slaughter.

“As far as legislation goes, the meat act has not been opened since 1906, so we’re working off the same legislation,” said Casey Gallimore, director of regulatory and scientific affairs at the North American Meat Institute (NAMI). “The only change that’s happened since then is poultry got added in with The Poultry Products Inspection Act [1957] and then you have the Humane Methods of Slaughter Act. But the actual ‘nuts and bolts’ that we work off of at the Meat Institute is the same act from 1906.”

The Humane Methods of Slaughter Act in 1958 addressed the suffering of animals during slaughter and not food safety, but The Poultry Products Inspection Act of 1957 applied the principles of The Meat Inspection Act of 1906 to poultry and poultry products, requiring federal inspection and prohibiting misbranding and adulteration. Another act did pass in 1967, filling in a few other gaps in the 1906 act.

The Wholesome Meat Act of 1967 added consumer protection to the 1906 act by addressing conditions not covered in the original law. Animals slaughtered for intrastate commerce did not fall under the federal inspection regulations of the 1906 law and were the responsibility of the state. Limited state funds opened the door for abuses and inadequate food safety. The 1906 law also left out imported products and rendering.

The new act in 1967 amended the 1906 act adding the regulation of transporters, renderers and cold-storage warehouses to the USDA’s authority, as well as requiring much stricter requirements on imported meat products. In addition, the new act extended the USDA’s jurisdiction over slaughter and processing for intrastate commerce and only allowed uninspected meat to go to the owner of a slaughtered animal.

As regulations, laws, government oversight and an understanding of the need to push food safety forward in light of significant events evolved, so too did the processes of ensuring food safety regarding all the periphery of the meat business.

Continued Evolution

As with all industry today, technology and the automation and machines that result from it continue to change manufacturing at a rapid pace. This change includes the meat and poultry industry, but meat and poultry processing maintains some uniqueness relative to most other manufacturing industries. People still provide much of the labor in processing.

“If you think about vehicle manufacturing or even a lot of food manufacturing, they can be done primarily with machines where employees are highlighting the machines,” Gallimore said. “Wherein our industry the predominant part of processing happens from employees, and machines highlight employees and help employees. It’s very different.”

Meat and poultry processing necessitates human labor due to the impossibility of every cow, hog, chicken, etc., to match an exact specification, size and weight needed for machines to adapt to the unavoidable variances. So many unique variables create an intricacy requiring human abilities. The reliance on, and need for, human skill and labor to carry out processing tasks has shaped the way the industry inspects for food safety, but that is changing.

“For a long time, the industry’s only ways of inspecting to see if things were good were just looking at it, smelling it and touching it,” Gallimore said. “Now, the environmental and product microbial sampling programs at these facilities are intense. They have all kinds of different things they’re testing for on very intricate schedules between areas of the plant or different types of products, different organisms that they’re looking at whether it’s pathogens or indicator organisms, so inspections are more based on what you can’t see and what really is causing illness.”

As inspection evolved and became better and more comprehensive due to science and academia, so did food safety. Industry began to realize when all companies provided safer food, the industry benefited. Because of that premise, over time a shift occurred and the processing industry began sharing information on food safety. Suppliers to the industry began to share information with not only their processor customers, but also with each other. Food safety became noncompetitive.

“At the end of the day, all the customer sees is that there is ground beef being recalled, and then they have a fear of ground beef,” Gallimore said. “So, we realized many years ago that we weren’t served by anyone doing better than anyone else on food safety because all of our products are looked at as very much the same thing.”

KatieRose McCullough, also a director of regulatory and scientific affairs at NAMI, related the same sentiment to worker safety in meat and poultry processing.

“[The meat and poultry] industry did the same thing with worker safety as well,” McCullough said. “It said, ‘this isn’t a competitive issue.’ In the spirit that all our employees are valuable because human life is valuable, and how do we best protect our workers in a noncompetitive space? We did a very, very similar thing when it came to worker safety as well.”

A direct relationship exists between food safety and worker safety. While USDA’s Food Safety and Inspection Service (FSIS), established in 1977 as the Food Safety and Quality Service (FSQS) and reorganized and renamed in 1981, oversees meat and poultry food safety and the Occupational Safety and Health Administration (OSHA), founded in 1971 after the Occupational Safety and Health Act of 1970 monitors worker safety, one always affects the other in the meat processing industry.

As the people pointing out the things employees might or might not be doing to ensure safety, personnel often share close relationships in meat packing plants.

“The other thing is that they’re both rooted in science and risk assessment,” Gallimore said. “So, you make decisions in food safety and worker safety based on data and risk assessment. That again is another reason why those two types of people in plants tend to have really close working relationships and really play off each other well.”

You might also enjoy:

Overcoming obstacles and chasing innovation, the pet food industry prepares for its promising future.

Today’s meat and poultry processors carefully manage expectations to feed people, preserve the planet and deliver profits in the future.

Modern Perspective

Legislation, science and academia eventually came together after an event in 1993 took food safety to a next level. An E. coli outbreak at San Diego-based Jack in the Box restaurants sickened more than 700, hospitalized 144 and killed four. This event prompted legislation mandating Hazard Analysis and Critical Control Point (HACCP) plans in 1996. Russell Cross, professor of Animal Science at Texas A&M University, and an original advocate for mandating HACCP in meat processing, said the regulations also applied to all state-inspected facilities as well as federally inspected facilities.

“And really when the United States mandated HACCP in 1996, they were effectively mandating HACCP for a good part of the world,” he added. “Because anything that’s imported into this country has to have a meat inspection system that’s equal to the US system. That impacted a lot of the countries around the world.”

In addition to all the legislation generated from “The Jungle” to government mandated HACCP plans, another and more slowly moving event shaped the evolution of food safety and continues to further it.

According to Frank Yiannas, Food and Drug Administration (FDA) deputy commissioner for food policy and response, while legislators responded to events that placed food safety issues in the public eye, and the food industry worked to make food safer, the food production and foodservice communities began to recognize the advancement of food safety needed more than just rules, testing, inspections and training. There needed to be a shift in the way people think.

“It requires a better understanding of human behavior and concepts of organizational culture,” Yiannas said. “In fact, you can have the best rules, policies and procedures written on paper, but if they’re not put into practice by people, they’re useless. But, widespread realization of that reality has been a long time coming.”

He added, “Increased interest in food safety culture has coincided with advances over the past 50 years in behavioral and social science research that have produced valuable insights into people’s thoughts, attitudes, and behaviors. So, you see, advances in understanding the technology of keeping foods safe and understanding the behaviors needed to keep foods safe have been advancing on parallel tracks.”

Company leaders must define food safety as an intrinsic value of the company, a non-negotiable thread of the fabric sewn into organizational culture. It is not a priority, but instead a guiding principle to how those in the food industry conduct business.

“Food manufacturers need to recognize that a food safety culture is not a communication plan, a tagline or a slogan,” Yiannas said.

Everyone from the C-suite to managers on the processing floor must make sure expectations concerning food safety are clear and communicate those expectations, as well as ensure all the knowledge and skills are in place to produce safe food. Investments in the design, or renovation of facilities, tooling and equipment selection and replacement and having experts on staff all play crucial roles in the production of safe food.

“It also includes managing food safety metrics and utilizing positive and negative reinforcement,” Yiannas said. “And it involves having knowledge of and leveraging proven behavioral science principles in your journey to strengthen a culture of food safety. Creating a food safety culture involves leveraging both food science and behavioral science.